The University of Miami team has brought together a wide range of expertise with contributors from Biomedical Engineering, Mechanical and Aerospace Engineering, Nursing, Bascom Palmer, Johnson and Johnson, Biochemistry, Medicine and Anesthesia, as well as the School of Architecture. Together, we have taken on a range of tasks including design and prototyping of an affordable ($100) ventilator, options for re-configuring ventilators to fit multiple patients, rapid prototyping of DIY personal protective gear, as well as testing elements in the form of nasal swabs. It is key to note the University's ability to bring together a team where leaders such as Professor Richard McNeer and Professor Ricardo Martinez-Ruiz are leading the efforts to design and develop the ventilator, as well as contribute feedback to the prototypes emerging from RAD and the Fabrication Lab, even while actively working in the front lines at the hospital. This has enabled our team to focus our efforts on realistic prototypes that have the ability to seriously impact our preparedness for the pandemic.

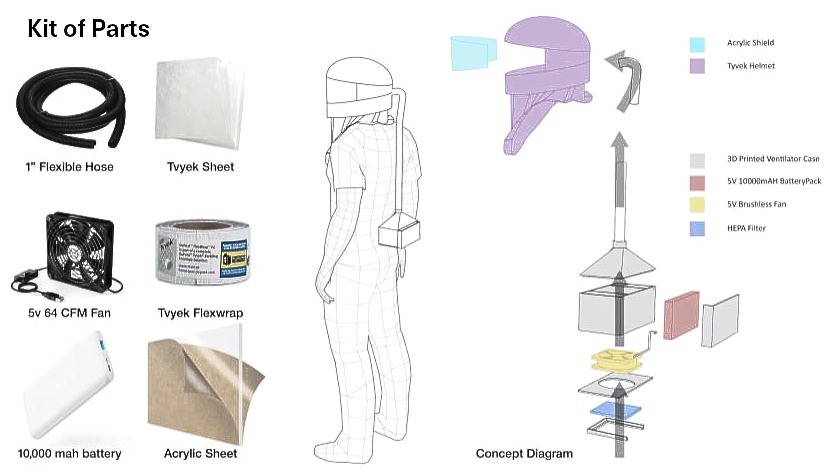

The School of Architecture has invested equipment, materials, and faculty and staff to work towards these solutions. We hope that these efforts will result in early emerging prototypes that should be complete within the first weeks of April and will continually be developed throughout this crisis. Currently, the School of Architecture is focusing its effort on a 3 pronged approach to maximize the impact of this research which revolves around producing swabs to immediately help the University of Miami Healthcare System test patients, the design of of PAPR mask, and 3D printed ventilator components. The nasal swabs which will utilize the School of Architecture's Formlab's printers have been developed by Formlabs in partnership with USF and tested by the FDA in on going effort to maximize the production of available nasal swabs. The PAPR mask, a positive air pressure mask made of laser cut tyvek, is currently being designed and reviewed by the medical team to test its efficiency compared to other alternative PP+E options. Lastly, and perhaps most importantly, the School of Architecture is working with Biochemistry faculty to 3D printed a ball valve that has the ability to allow two users of the same ventilator with different lung mechanics to use the same ventilator and potentially a valve that would work with four patients. Typically multi-use ventilators are limited to patients with similar lung mechanics which limits who may be able to use an open spot on a ventilator, this development will remove these limitations and make a major difference in increasing ventilator access. We will continually strive to improve these designs with our growing team of professionals across the University of Miami network in hopes of producing tangible results to help in this ongoing pandemic.

The School of Architecture has invested equipment, materials, and faculty and staff to work towards these solutions. We hope that these efforts will result in early emerging prototypes that should be complete within the first weeks of April and will continually be developed throughout this crisis. Currently, the School of Architecture is focusing its effort on a 3 pronged approach to maximize the impact of this research which revolves around producing swabs to immediately help the University of Miami Healthcare System test patients, the design of of PAPR mask, and 3D printed ventilator components. The nasal swabs which will utilize the School of Architecture's Formlab's printers have been developed by Formlabs in partnership with USF and tested by the FDA in on going effort to maximize the production of available nasal swabs. The PAPR mask, a positive air pressure mask made of laser cut tyvek, is currently being designed and reviewed by the medical team to test its efficiency compared to other alternative PP+E options. Lastly, and perhaps most importantly, the School of Architecture is working with Biochemistry faculty to 3D printed a ball valve that has the ability to allow two users of the same ventilator with different lung mechanics to use the same ventilator and potentially a valve that would work with four patients. Typically multi-use ventilators are limited to patients with similar lung mechanics which limits who may be able to use an open spot on a ventilator, this development will remove these limitations and make a major difference in increasing ventilator access. We will continually strive to improve these designs with our growing team of professionals across the University of Miami network in hopes of producing tangible results to help in this ongoing pandemic.