A suspension system to maneuver seamlessly through ragged terrain. A bucket ladder that efficiently scoops simulated lunar soil. A conveyor belt that deposits payload into a custom-built box.

These are just a few of the unique features that set the University of Miami’s rover apart at this year’s NASA Lunabotics Challenge at the Florida Space Institute in Orlando, where teams from across the country competed to design and build robots capable of performing tasks in a lunar-like environment.

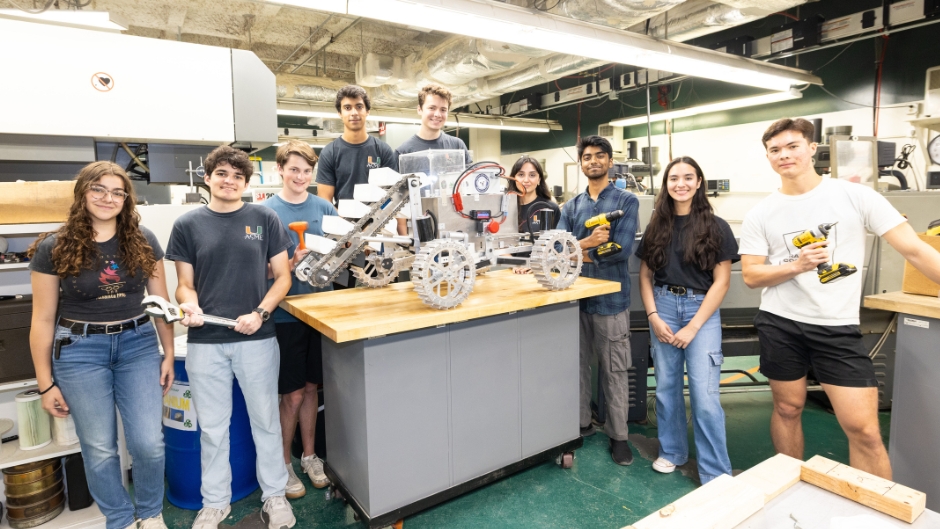

Built by students from the College of Engineering, the University’s Lunabotics team, made up of students from the American Society of Mechanical Engineers (ASME), spent the academic year building a telerobotic rover designed to tackle a moon mission simulation. The rover’s main task: excavate lunar rock and soil and deposit it into a berm structure, mimicking NASA’s vision for future lunar infrastructure.

“What set our design apart from other universities, especially in terms of mobility, was that we were one of the few teams to incorporate a suspension mechanism into our rover design,” said Lizi Ebralidze, president of the University’s ASME chapter. “This feature significantly improved our rover's movement, allowing it to navigate the uneven and challenging lunar-like terrain with greater ease and stability.”

The team’s attention to detail extended to power management. After careful analysis and trade studies, they selected energy-efficient motors and optimized each subsystem to minimize energy consumption. That unique feature earned them NASA’s Most Energy Efficient Rover award.

Behind the scenes, the students leaned heavily on skills learned in foundational engineering classes, including Intro to Engineering II and Mechanical Design. They used SolidWorks to build detailed 3D models of the rover and worked with machinist Demetrios Doumenis, Jr. to manufacture critical components, including the complex trencher system.

The team also collaborated with several Ph.D. students and faculty members whose support played a key role in the rover’s performance. Shruti Choudhary, a Ph.D. student, contributed a dust particle sensor known as APT, which allowed the rover to monitor regolith particle levels in real time and protect sensitive components. Russell Roberts, a Ph.D. student in the Department of Physics, also made significant contributions to the project and served as the team’s faculty advisor during the competition at the University of Central Florida. In addition, Emrah Celik, faculty advisor for the University’s ASME chapter, provided key support and guidance throughout the build process.

But success wasn’t without adversity. During the first round of competition, the trencher mechanism was damaged causing a major setback with limited time and resources to fix it.

“We even considered driving back Miami to make a new part,” Ebralidze said. “Instead, we bought a hand Dremel and a diamond bit, manually cut steel, and reinforced the part ourselves. The trencher worked flawlessly, and we were able to continue competing without further issues. This moment was a true testament to our teamwork, resourcefulness, and determination.”

That resilience earned the team the Leaps and Bounds Award, recognizing the team’s significant growth and engineering maturity compared to the previous year. They were also awarded third place in Presentation and Demonstration for effectively communicating their rover’s capabilities and design to NASA’s judges.

“We learned a lot during the competition, including how to work as a team in tough situations and act like true engineers,” Ebralidze said.

The Lunabotics Challenge is one of many national competitions that showcase the innovation and hands-on learning happening at the College of Engineering. With their sights already set on next year’s rover, the students plan to build on the lessons learned and keep pushing boundaries.