Not long ago, Doyoung Chang, Ph.D., was designing robots that may be climbing—and cleaning—the walls of skyscrapers one day. Now the biomechanical engineer is intent on perfecting a robotic arm that helps cancer fighters at Sylvester Comprehensive Cancer Center and across the University of Miami Health System obliterate small tumors with a heat-delivering needle inserted through the skin.

“They may have different uses but they share many parts,” said Chang, research associate professor at the Miller School of Medicine, about the industrial robots he patented in his native South Korea and the needle-driving robots he is developing in the Interventional Oncology Robotics Laboratory he recently opened for the Department of Interventional Radiology. “It’s how you apply the principles that differ.”

What captures much of Chang’s attention these days is figuring out how a robotic arm can accurately steer an image-guided needle through tissue, fat, organs and other obstacles that would alter the needle’s programmed course, causing it to miss a targeted tumor. But he’s ready to collaborate with other researchers across the University on their innovative ideas for new approaches to resolve the everyday problems they encounter.

“We’re like a robotics machining workshop, and we are open to new projects where we could provide synergy, even those unrelated to medical,” said Chang, who joined the U after three years at Johns Hopkins University Medical School, where he completed his post-doctoral training in the urology robotics lab—and found his calling. “There are two routes to do this kind of robotics work: Design it in-house, then out-source the manufacturing. Or do both in-house. I choose the latter route for our lab.”

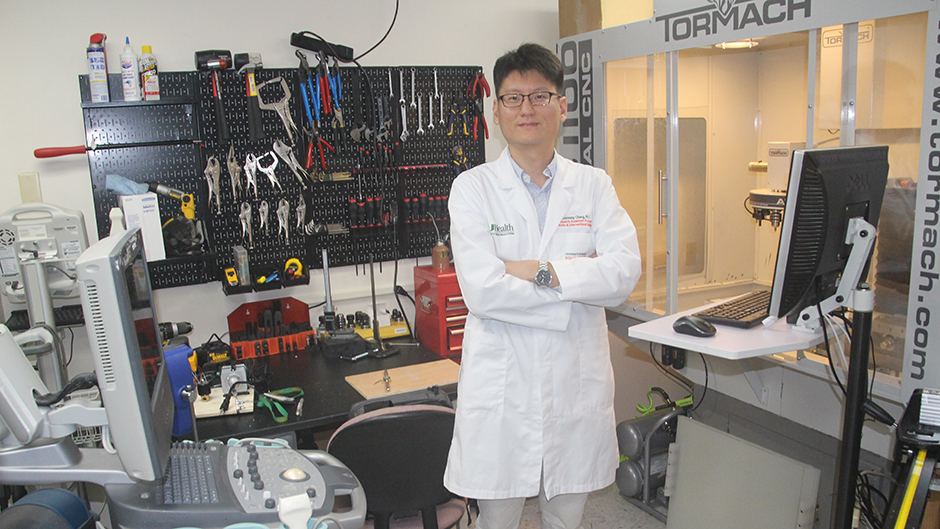

Tucked among the warren of Department of Physiology and Biophysics labs on the fifth floor of the Rosenstiel Medical Science Building, the one-room lab is tiny, but it is fully equipped to move ideas from the concept and design phases through manufacturing, testing and trial. Taking up half of one wall is a CNC (Computer Numerical Control) milling machine that can automatically chisel the parts Chang or a student assistant from the College of Engineering—he’s had four so far—design on a computer from raw sheets of metal or other material.

Hanging on the adjacent wall is a pegboard with an array of wrenches, pliers, screwdrivers, and other more rudimentary tools needed to assemble disparate parts into working machines. Across the room, not far from an ultra sound machine, sits a pair of 3D printers.

For now, Chang’s desk is cluttered with multiple computer screens and haptic controllers—think computer game joysticks—that can maneuver the needle-driving robot that sits on a nearby cart. The device, an arm with a platform for a needle that looks like it belongs to an industrial sewing machine, is not itself new. But Chang hopes to improve its ability to help interventional radiologists more accurately target cancerous tumors with needle-delivered radiofrequency ablation, microwave ablation, or cryotherapy.

Guided by static images from a CT or MRI scan, or a real-time image from an ultra sound, interventional radiologists have for decades been steering needles through patients by hand or with the help of a robot to deliver such minimally invasive treatments. Such interventions have many advantages over traditional surgery, including less risk and pain, shorter recovery times and improved outcomes.

But, Chang says, good outcomes depend on a physician’s skill at placing the needle, and based on the images he or she uses for guidance, steering it toward its target—a difficult task that relies on precise eye measurement, plenty of practice, and multiple images along the needle’s journey that expose patients to radiation.

Robots are more accurate in placing the needle, Chang says, but they cannot match an interventional radiologist’s skill at compensating for the slightest movement that can alter the needle’s course. Even a patient’s breathing, or the deflection of tissue that occurs when the needle pierces an organ can detour the needle from its target.

So for his new lab’s inaugural project, Chang is working on developing what he calls “cooperative human-robot needle steering,” which would allow physicians to utilize the robot’s more accurate navigation, but rely on their own skills and knowledge to adjust the needle for movement.

“Right now, physicians drive with a map in their heads, rather than with GPS,” Chang said. “We want to provide them a GPS and driver assistance that doesn’t change their driving style but gives them the benefits of this technology.”

Lucky for biomechanical engineering students like Jessica Roach, who worked in the new lab before graduating in May and heading to a medical device company in Texas, Chang’s passion for finding solutions is infectious.

“Working in his lab was amazing,” said Roach, who helped design and manufacture a phantom abdominal cavity that mimics respiratory movement and tissue stiffness. “My favorite part was taking the phantom model to the physicians (in the Department of Interventional Radiology) to test and see their reaction. They were excited and had great feedback. It was really rewarding.”

To learn more about the collaborative services or the opportunities for engineering students available at the Interventional Oncology Robotics Laboratory, contact Chang at dchang@med.miami.edu.