Perhaps British science fiction writer Arthur C. Clarke was onto something. In his Space Odyssey book series, he created a fictional lunar settlement called Clavius Base, a mammoth complex that includes structures, a landing pad, and control tower.

So named because it is located near one of the moon’s largest craters, it is featured in both the novel and film versions of 2001: A Space Odyssey.

Now, 50 years after the historic Apollo 11 mission, NASA is making plans to return astronauts to Earth’s only natural satellite—and this time, it intends to build a permanent base on the lunar surface, making Clarke’s vision of colonizing the moon a reality.

It will be an ambitious undertaking, indeed, one that’s easier said than done, for the cost of transporting payloads like building materials into space can be pricey, costing as much as $10,000 per pound.

A University of Miami researcher, however, is trying to perfect a technique that would significantly reduce the amount of cargo NASA would have to haul to the moon to build a permanent settlement.

The solution?

“Use the lunar soil that’s already there to build structures,” said Ali Ghahremaninezhad, an associate professor and civil materials engineer in the College of Engineering.

Fine as flour and rough as sandpaper, lunar soil is similar to fly ash, a byproduct of coal-fired electric generating power plants which, when mixed with certain chemicals, forms a compound similar to Portland cement. “Fly ash has been used as an additive to improve the durability of concrete for quite some time,” said Ghahremaninezhad. “So the idea is to use some of the techniques we’ve developed here on Earth and apply them to the soil on the moon.”

Scientist-astronaut and lunar module pilot Harrison Schmitt uses an adjustable sampling scoop to retrieve lunar soil samples during the Apollo 17 moon mission of 1972, the final mission of NASA’s Apollo program.

Tests conducted on lunar rocks, core samples, pebbles, sand and dust brought back to Earth during the six Apollo missions between 1969 and 1972 have confirmed lunar soil’s similarity to fly ash. But it will take something much more potent than water to activate the soil’s cement-like properties. And that’s where Ghahremaninezhad’s NASA-funded project comes in.

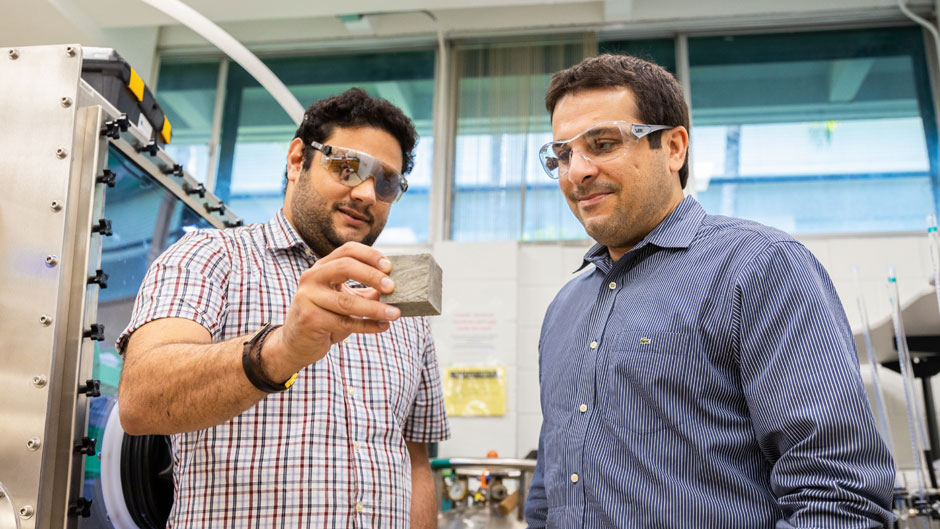

Inside his College of Engineering laboratory, he is testing different materials to determine which would be most effective in turning lunar soil into a hardened, concrete-type substance. Some call it “mooncrete.”

Much of the 842 pounds of rocks and soil brought back from the moon has already run out, used in scientific research and analysis almost immediately after arriving on Earth. So for his testing, Ghahremaninezhad is using a lunar regolith simulant synthesized to approximate the chemical properties of real lunar soil.

“We’ll absolutely still need to transport some materials to the moon. There’s no getting around that,” explained Ghahremaninezhad. “But the goal is to minimize cargo and perfect a method that will lead to mass construction projects on the lunar surface.”

Equally as important: the structures built from lunar soil must be sturdy enough to protect astronauts from the harsh conditions on the moon, which can be a dangerous place to live, serving up a hostile environment that includes everything from extreme temperature variations and radiation to meteor strikes and even the lunar soil itself, which can cut like glass.

While Ghahremaninezhad’s research is still in the early stages of testing, some of the small, hardened blocks he has produced from the simulant have performed well under testing, withstanding different pressure loads and exposure to extreme hot and cold.

“It’s no longer a dream; we’re going back to the moon and beyond,” said Ghahremaninezhad, referring to NASA’s plans for the human exploration and colonization of Mars. “And like the Apollo moon missions, we’ll need new technology to accomplish that. My research is part of the bigger picture.”