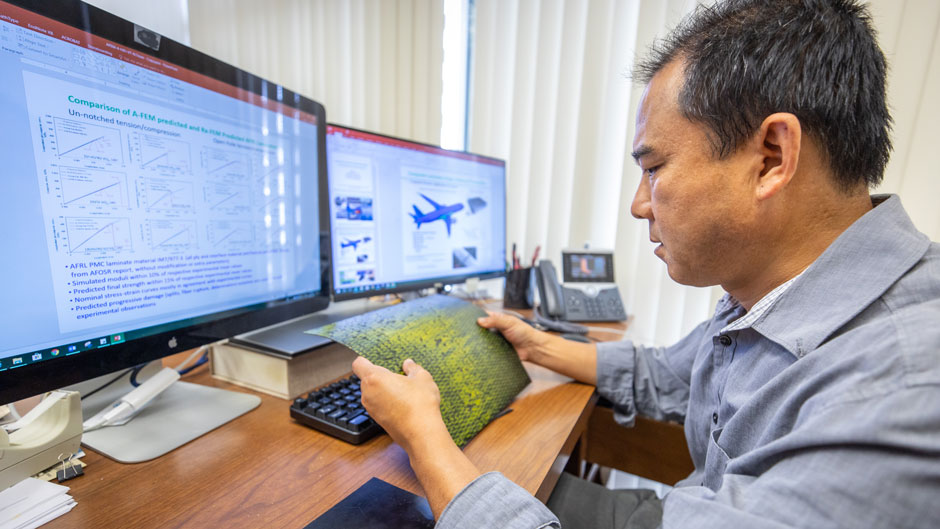

Thinner than a human hair, the single strand of carbon fiber Qingda Yang displayed on his desktop computer screen looked as brittle as dry spaghetti. But don’t be fooled by the filament’s fragile appearance, the University of Miami professor of mechanical and aerospace engineering advised.

When twisted like yarn and combined with other carbon fibers, the strand becomes part of a lightweight woven mat of composite material that can be five times as strong as metal.

For the aviation industry, composites and their high strength-to-weight ratio, said Yang, have been “a game changer,” replacing aluminum and steel as the preferred material used to fabricate the fuselage and wings of passenger airliners—a manufacturing evolution that makes aircraft lighter and more fuel-efficient.

In one aspect, though, composites can be an enigma.

“The aviation industry has decades of experience with aluminum, and we’ve been able to study how it fatigues, which has allowed for rigorous maintenance schedules for aircraft,” said Yang. “But we don’t have a long history with composites. Their use in commercial passenger planes is still relatively new, so there’s some uncertainty as to their long-term durability.”

“The aviation industry has decades of experience with aluminum, and we’ve been able to study how it fatigues, which has allowed for rigorous maintenance schedules for aircraft,” said Yang. “But we don’t have a long history with composites. Their use in commercial passenger planes is still relatively new, so there’s some uncertainty as to their long-term durability.”

Yang is out to change that.

With a grant from aviation giant Boeing, the UM materials engineer is developing an analytical tool that will help the industry learn more about the fatigue and failure properties of composites. His tool, called an augmented finite element method, will simulate the use and predict the life and residual strength and stiffness of composite materials in aircraft over an extended period.

“When does it begin to wear down? What type of damage can be expected after so many takeoffs and landings? How long will it continue to be safe even after it develops cracks? Those are the questions that need to be answered,” said Yang.

“At the end of our research, Boeing wants to understand and have confidence that our analysis can be used to predict the life, remaining strength and remaining stiffness of composite airframe structures,” explained Yang.

Composites are changing the airline industry, he said. Boeing’s 787 Dreamliner, he noted, is the first major commercial airliner to use composites as the primary material in its airframe—the plane is about 50 percent composite by weight, 80 percent by volume.

Yang said his research can be applied to all current and future aircraft made with composites.

“It’s important for university researchers to work hand-in-hand with engineers in industrial companies to ensure that their work has impact beyond classroom walls,” said Yang, a former Rockwell engineer who actually helped in the design of the 787 and also worked on the heat-resistant tiles of the Space Shuttle. “Developing the capability to predict composite strength and durability is bound to have industry-wide implications.”